Autonomous Material Transport - Consist of AGV - Automatic Guided Vehicle, AMR - Autonomous Mobile Robot, ACR - Autonomous Case Hnadling Robot and APR - Autonomous Pallet Handling Robot. It is a computer-controlled, wheel-based vehicle that can travel where it assign to go. It does not require an onboard operator. To operate, instead, there will be a combination of sensors and software. These two things guide it over a predictable pathway that is preset by the needs of the warehouse. They can be loaded, dispatched to the drop point for that inventory, and return without help. They do not tie up employees for the mundane task of riding from one point to another. Instead, operators that would normally be kept on the forklift are free to take care of other tasks. They simply have to wait on the automated vehicle to return, doing other things while they wait. This can help to improve the productivity and efficiency of manufacturing and intralogistics operations.

The largest range of AGVs available in the market and thousands have been deployed in the manufacturing floors. There are many designs and applications such as Tunnel Towing, Platform lifting, Tug Towing, Conveyor, Co-Bot, Forklift. System integration to ERP, MES, WMS with API interface done by our expertise. Below are some of our Mobile Robots:

.png)

2 Way Automated Guided Vehicle

Guidance: Magnetic

Load Capacity: Up to 1000Kg

.png)

Tugger Automated Guided Vehicle

Guidance: Magnetic/ Laser Guidance

Load Capacity: Up to 1200Kg

.png)

Automated Forklift Truck

Guidance: Laser Guidance

Load Capacity: Up to 1000Kg

.png)

HIKROBOT Latent Mobile Robot

Guidance: QR Code

Load Capacity: Up to 600Kg

_edited.png)

MEGVII Matrix 8

System: AI + AS/RS 3D Pallet Shuttle +

AMR + Picking Solution

SEER SJV-SW600

Guidance: LASER SLAM

Load Capacity: 600Kg

Intelligent Scribing Robot

(Construction Robot)

Guidance: LASER TRACKER

Marking Accuracy: ±3mm

.png)

1 Way Automated Guided Vehicle

Guidance: Magnetic

Load Capacity: Up to 500Kg

.png)

4 Way Automated Guided Vehicle

Guidance: Magnetic/ SLAM Navigation

Load Capacity: Up to 2500Kg

.png)

Unit Load Automated Guided Vehicle

Guidance: QR Code/ Laser Guidance/ SLAM

Load Capacity: Up to 1200Kg

HIKROBOT Autonomous Carton-Transfer Unit ( CTU)

Guidance: IMU/ QR Code

Load Capacity: Up to 250Kg

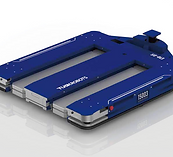

TUSKROBOTS E10

APR Creator

Guidance: SLAM/ QR Code

Load Capacity: 1000Kg

SEER SFL-CDD14 FMR

Guidance: LASER SLAM

Load Capacity: 1400Kg

Floor Tile Paving Robot P900

(Construction Robot)

Guidance: LASER SLAM

Load Capacity: 950Kg